There is a good reason for using internal combustion engines instead of steam engines in our modern world. IC engines are very portable and very fuel efficient. A gasoline engine is about 20-30% efficient, while a steam engine of the type I’m working with will get between 8 and 15%.

In other words, an IC is about twice as efficient as a steam engine.

Having said that, most of the power you use comes from steam. Instead of using a reciprocating engine, we use turbines in the modern era. We still boil water and use the pressure from the steam to get radial motion, which is converted into power. You get that power in the form of electricity.

When you hear about coal power plants, or nuclear power plants, the difference between them is the fuel used to heat the water, not the electrical generators.

The advantage of steam, for me, is that I can use almost any fuel to generate the steam.

Fuel For Steam

Depending on the design of your boiler, it can use wood, coal, propane, natural gas, gasoline (bad), kerosene, diesel, or a host of other fuels. The only requirement is that the firebox be able to handle the fuel and the temperature generated by that fuel.

Coal was often used for locomotives. It produces more BTUs per pound than does wood. It burns hotter and typically longer than wood. Plus, it will keep for a fairly long period of time. The downside of using coal is that it emits sulfur dioxide (SO_2) which will eat at almost anything it touches. It is a primary source for “acid rain”.

This means that burning coal is hard on your firebox, fire tubes, and smoke box/stack. It is why many restored locomotives use wood instead of coal to fire the engines.

I want to be able to use coal or wood but have a burner that can be put into the firebox as needed that will burn liquid fuels. I have an axe, I have trees and fallen branches, I can make steam.

I will buy coal in fifty pound bags and that will provide steam for hours and hours.

Types of Boilers

There are two primary types of boilers and one “toy” boiler. We’ll start with that toy.

With a toy boiler, you have a tube filled with water; you heat the tube up, it creates steam, you tap the steam off the top of the tube.

The boiler I used for my first live steam test was a pressure cooker. I attached a hose to the rocker port and then the other end to the steam engine, a simple double-acting wobbler.

Skip about halfway to see it actually running.

A boiler of this type wastes much of the heat that is put into the system. It can make high pressure steam but at a fairly low rate.

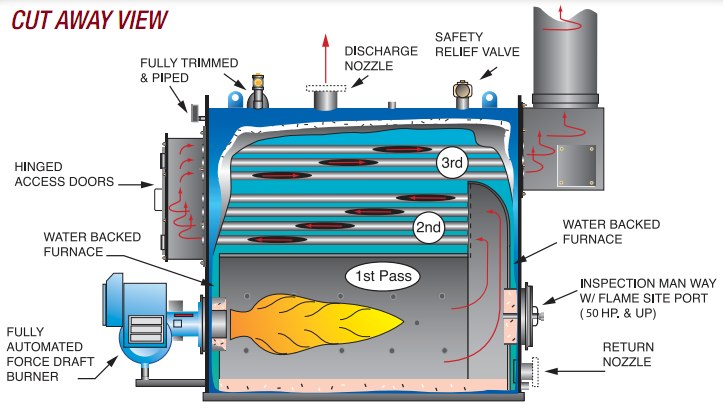

The next type of boiler is a firetube boiler.

A firetube boiler captures more of the heat put into the system by routing the fire through a series of tubes surrounded by water. The goal is to extract as much heat from the fire and gases as possible and still have a good fire.

Water completely covers the firebox. The hot gases then pass up into the first set of fire tubes, which brings the hot gases through the water back to the left side of the image. The hot gases are then mixed back together and pass forward through the third stage before being exhausted to the outside air.

The design criteria include the size of the fire tubes, the length of the tubes, and the surface area of the tubes.

A small diameter tube has more surface area per given length of tube because we are measuring the ID of the tube. For small tubing, the wall thickness adds a larger percentage to the OD than for larger IDs. But as the cross-section of the tube goes down, the velocity through the tube goes up. A smaller pipe requires a faster flow to move the same amount of gas.

As the diameter grows, the required size of the walls of the pipe also goes up. This creates a balancing act. You also need some way to create draft as the fire is starting.

The pressure is working to crush the tubing; this is the right direction for the strongest vessel with the thinnest walls.

This is the standard for boilers from 200 years ago through today. As long as you have enough water in the boiler it will be a very safe boiler.

Water Tube Boiler

This type of boiler runs water through the tubes inside the firebox. It is a faster method of getting to steam pressure but has some downsides.

Water enters at the top left at room temperature or lower. It is pushed through some lazy coils within the firebox to warm it up but not to create steam. It is then added to the very hot, near boiling water in the separating drum. From there it is pulled down and pushed back into the firebox at the bottom.

As the water moves through the coils, it absorbs more and more heat until it wants to boil but can’t because it is held under pressure. When it finally reaches the steam separating drum, again, the steam is free to escape; it boils.

That hot steam is still carrying too much water; it is considered saturated. As it is tapped off the top of the separating drum, it travels back through the firebox for a third time; this time it is being pushed by pressure, not pumps.

During this third trip through the boiler, it is “super heated” which is to say, it becomes so hot and the pressure so high that it is no longer considered saturated.

In other words, it is “dry” steam.

This type of boiler requires two pumps, one that can inject water against high pressure. The other is actually running at “normal” pressures. While the contents of the pipes is at a higher pressure, the inlet pressure and the outlet pressure only differ by a small amount, as compared with the feed pump, which is working against 150 psi or more.

The Ofeldt Boiler

My Ofeldt was attempting to design a better still, for making alcohol; he designed this instead:

In this design there are no circulating pumps. The water is injected into the central drum, where it mixes with the hot, nearly boiling water.

“Cold” water flows to the bottom where it enters the coils. The coils are in the hot gases of the combustion chamber. As the heat transfers to the water, the water starts to rise. As the water absorbs more and more heat, it starts to change phases. As it enters the gas phase it collects at the top of the central drum. From there, a pipe will lead down the side to a pancake coil at the bottom, closest to the burner. This is the superheating stage.

From there, the superheated steam is sent to the engine.

This is a very compact design that works well for small spaces. The firebox can burn any fuel with the correct grating and burners.

This is the boiler or steam generator I plan to make.

Design

I am not a good welder. I will need to be better to make this boiler.

The central tank will be schedule 80 black pipe, as large as I can afford. It will have pairs of threadolets added for each coil, top and bottom.

To the threadolets will be 1/4 NPT, which will connect to an adaptor from 1/4 NPT to double ferrule compression fittings. This means that I will be able to weld the threadolets on with full 360 access to the root. Giving me a higher possibility of success.

After each thradolet or set of threadolets is welded in place, I’ll add the adaptor and then a capped plug. This allows me to do a hydrostatic test of the boiler chamber one weld at a time. And when I start adding the coils, one coil at a time.

I’m hoping for 4, 6 or 8 sets of coils. I think I can do this.

As they say, a grinder and paint makes me the welder I aint.

According to my research, the boiler I’m describing should produce more than enough steam at a high enough pressure to drive the steam engines I’m designing.

If it works, I’ll look into having a real boilermaker make them for me. And be shocked at the price.

P.S.

I read your feedback on this blog. One of the things I realized is that I often write articles that allow me to set down my thoughts and ideas logically. I’m putting my reasoning into words to break cycles of indecision.

Yesterday’s article about cycles is more like how my mind runs normally. I’ll be thinking about something which circles back to the original thought, which will take me in a different direction for another rabbit hole which then cycles back to the same driving force. Frequently without ever reaching a conclusion.

For those that know me in person, it doesn’t look like this from the outside. It just looks like a nearly instantaneous leap to a correct or at least an excellent starting point.

good post Sir! i know very little about steam engines.

have you looked at Stanley Steamers boiler? they were on a small scale as they were automobiles.