I think Charlie Kirk would agree with one of the lesser-known heroes of the American Revolution

“I regret that I have but one life to give for my country.” – Nathan Hale, Sept. 22, 1776

in no particular order

Utah officials deliver update on Charlie Kirk assassination investigation, security at event – by Cooper Williamson, 10Sep2025

https://www.theblaze.com/news/utah-officials-deliver-update-on-charlie-kirk-assassination-investigation-security-at-event

Charlie Kirk assassination witness says shot did not come from the crowd – by Andrew Chapa, 10 sept2025

https://www.theblaze.com/news/charlie-kirk-shooting-witness-rooftop

‘You woke us the f**k up!’ Greg Gutfeld fires off message on Fox News after assassination of Charlie Kirk – by Carlos Garcia, 10Sept2025

https://www.theblaze.com/news/greg-gutfeld-charlie-kirk-woke

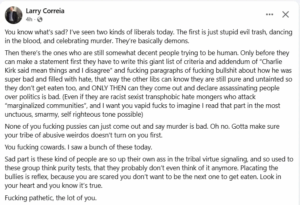

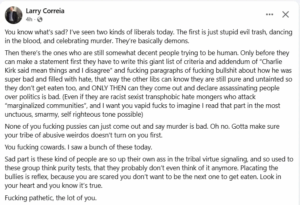

Leftists show their true colors after Charlie Kirk is shot — and it’s absolutely sickening – byChris Enloe, 10Sept2025

https://www.theblaze.com/news/leftists-show-their-true-colors-after-charlie-kirk-is-shot-and-it-s-absolutely-sickening

The Morning Briefing: Assassination and the Watershed Radicalization of the American Right – by Stephen Kruiser, 11Sep2025

https://pjmedia.com/stephen-kruiser/2025/09/11/the-morning-briefing-assassination-and-the-watershed-radicalization-of-the-american-right-n4943527

Trump Vows to Hunt Down Everyone Involved in Charlie Kirk’s Assassination – by Katie Pavlich 10Sep2025

https://townhall.com/tipsheet/katiepavlich/2025/09/10/trump-remarks-from-white-house-charlie-kirk-n2663104

The NYT’s Obituary for Charlie Kirk Is an Absolute Disgrace – by Matt Vespa, 11Sep2025

https://townhall.com/tipsheet/mattvespa/2025/09/11/the-nyts-obituary-for-charlie-kirk-is-an-absolute-disgrace-n2663115

They Murdered Charlie Kirk and They Must Pay – by Kurt Schlichter, 10Sep2025

https://townhall.com/columnists/kurtschlichter/2025/09/10/they-murdered-charlie-kirk-and-they-must-pay-n2663112

Did TMZ Staffers Cheer About Charlie Kirk’s Assassination? The Video Is Damning. – by Matt Vespa, 11Sep2025

https://townhall.com/tipsheet/mattvespa/2025/09/11/did-tmz-staffers-cheer-about-charlie-kirks-assassination-the-video-is-damning-n2663122

After Charlie Kirk Was Assassinated, Dems Kept Saying This Phrase. It Was a Little Jarring. – by Matt Vespa, 11Sep2025

https://townhall.com/tipsheet/mattvespa/2025/09/11/after-charlie-kirk-was-assassinated-dems-kept-saying-this-phrase-it-was-a-little-jarring-n2663107

What Comes After Charlie Kirk’s Assassination An anti-revolutionary’s death brings a new reckoning – byBen Domenech, 11Sep2025

https://thetransom.com/p/what-comes-after-charlie-kirks-assassination

“Dark Moment For America” – Trump Addresses The Nation After Kirk Assassination – by Tyler Durden, 11Sep2025

https://www.zerohedge.com/political/shots-reportedly-fired-charlie-kirk-event-utah-valley-university

Charlie Kirk’s blood is on the left’s hands – by Maureen Steele, 11Sep2025

https://www.bizpacreview.com/2025/09/11/charlie-kirks-blood-is-on-the-lefts-hands-1584140/

Two days before he was killed, CNN went on the offensive against Charlie Kirk – by Vivek Saxena, 11Sep2025

https://www.bizpacreview.com/2025/09/11/two-days-before-he-was-killed-cnn-went-on-the-offensive-against-charlie-kirk-1584159/

Obama actually says we have no idea what motivation was for Charlie Kirk assassination – by Mariane Angela, 11Sep2025

https://www.bizpacreview.com/2025/09/11/obama-actually-says-we-have-no-idea-what-motivation-was-for-charlie-kirk-assassination-1584072/

Kirk Assassination Police Audio Leaks, Contains First Full Description of Suspected Killer Along With Exact Location –

By C. Douglas Golden, 11 sep2025

https://www.westernjournal.com/kirk-assassination-police-audio-leaks-contains-first-full-description-suspected-killer-along-exact-location

What happens after Charlie Kirk? – The killing of a political commentator may mark the moment America stopped being insulated from the grip of ideological violence. – by Zahra Sethna and Stephen Mostad ,11Sep2025

https://www.collapselife.com/p/what-happens-after-charlie-kirk

Law Enforcement Announces ‘Breakthroughs’ in Charlie Kirk Investigation – by Jack Davis, 11Sep2025

FBI Provides News on Kirk Assassination, Including Details About the Weapon and Shooter – by Bonchie, 11sep2025

Internal Memo Reveals New Details About Weapon Used in Kirk Assassination, Engravings on Recovered Rounds – by Matt Margolis, 11Sep2025

“ATF and other law-enforcement located an older model imported Mauser .30-06 caliber bolt action rifle wrapped in a towel in a wooded area near the campus. The location of the firearm appears to match the suspect’s route of travel.” “The spent cartridge was still chambered in addition to three unspent rounds at the top fed magazine. All cartridges have engraved wording on them, expressing transgender and anti-fascist ideology.”

Why Charlie Kirk’s assassination will change us in ways this generation has never seen – by Christopher Bedford, 11Sep2025

If you think Charlie Kirk’s assassin was a one-off crazy, note the haters showing up to his vigils – by Frieda Powers, 11Sep2025

University of Michigan professor says Charlie Kirk’s assassination is ‘solution’ to ‘violent rhetoric’ – by Nicole Silverio, 11Sep2025

…”the assassination of Turning Point USA founder Charlie Kirk is a “solution” to “violent rhetoric spewed by empowered people.””

Charlie Kirk Assassination: What We Know…Or, More Accurately, Don’t Know – By Tom Knighton, 11Sep2025

https://miguelgg.substack.com/p/september-keeps-smelling-of-death

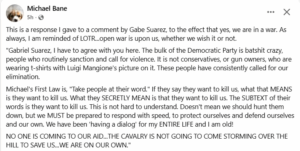

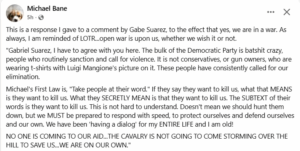

Twenty four years ago, we were attacked and we got to witness the enemies of our country dance and pass celebratory sweet pastries in the Middle east.

Yesterday we were attacked once again, but the dancing and celebration was done by people inside our country.

We are at war once again.

Memes by Themes #20: The Intellimafia – by Margaret Anna Alice, 11Sep2025

https://margaretannaalice.substack.com/p/memes-by-themes-20-the-intellimafia

The Morning Briefing: Assassination and the Watershed Radicalization of the American Right – by Stephen Kruiser, 11Sept2025

https://pjmedia.com/stephen-kruiser/2025/09/11/the-morning-briefing-assassination-and-the-watershed-radicalization-of-the-american-right-n4943527

Trump Vows to Hunt Down Everyone Involved in Charlie Kirk’s Assassination – by Katie Pavlich 10sept2025

https://townhall.com/tipsheet/katiepavlich/2025/09/10/trump-remarks-from-white-house-charlie-kirk-n2663104

Leftists and Muslims Celebrate Kirk Assassination – by Pamela Geller, 10Sep2025

https://gellerreport.com/2025/09/leftists-and-muslims-celebrate-kirk-shooting.html/?lctg=92233992

ASSASSINATED: The Great Charlie Kirk Shot Dead – by Pamela Geller, 10Sep2025

https://gellerreport.com/2025/09/assassinated-the-great-charlie-kirk-shot-dead.html/?lctg=92233992

Two days before he was killed, CNN went on the offensive against Charlie Kirk – by Vivek Saxena, 11Sep2025

https://www.bizpacreview.com/2025/09/11/two-days-before-he-was-killed-cnn-went-on-the-offensive-against-charlie-kirk-1584159/

Utah Gov Spencer Cox reminds America that the the state still has death penalty in the wake of Charlie Kirk’s assassination –

by Harold Hutchison, 11Sep2025

https://www.bizpacreview.com/2025/09/11/utah-gov-spencer-cox-reminds-america-that-state-still-has-death-penalty-in-wake-of-charlie-kirk-assassination-1584074/

Obama actually says we have no idea what motivation was for Charlie Kirk assassination – by Mariane Angela, 11Sep2025

https://www.bizpacreview.com/2025/09/11/obama-actually-says-we-have-no-idea-what-motivation-was-for-charlie-kirk-assassination-1584072/

What happens after Charlie Kirk? – The killing of a political commentator may mark the moment America stopped being insulated from the grip of ideological violence. – by Zahra Sethna and Stephen Mostad ,11Sep2025

https://www.collapselife.com/p/what-happens-after-charlie-kirk

September keeps smelling of death.- by Miguel Gonzalez, 11Sep2025

https://miguelgg.substack.com/p/september-keeps-smelling-of-death

Witnesses say ‘there was not enough security’ prior to horrific Charlie Kirk assassination by Andrew Chapados & Rebeka Zeljko, 11Sep2025

https://www.theblaze.com/news/charlie-kirk-witnesses-security-team

The Intent of the Charlie Kirk Assassination Continues With the Media’s Reaction: They Demand Our Silence By Brad Slager, 11Sep2025

https://redstate.com/bradslager/2025/09/11/the-intent-of-the-charlie-kirk-assassination-is-displayed-in-the-media-reactions-they-demand-our-silence-n2193838

The paths forward – Responding to the assassination of Charlie Kirk – by Surak, 11Sep2025

https://surak.substack.com/p/the-paths-forward

Where are the riots, like after the drug overdose death of George Floyd? An assassin destroyed Charlie Kirk’s jugular vein while he was on a university campus answering a question regarding transgender ultraviolence. The ammunition had written messages on it supporting transgender ultraviolence. We have been warned sternly by the “experts” about the “fascist” nature of America’s Christian majority, yet for some reason, those Christians are going about in quiet prayer.

Dana Loesch: ‘Restorative Justice’ Killed Ukrainian Refugee – By Tom Knighton, 11Sep2025

https://bearingarms.com/tomknighton/2025/09/11/dana-loesch-restorative-justice-killed-ukrainian-refugee-n1229868

but wait – there’s more

Judge’s ‘promise’ let career criminal walk free to butcher Ukrainian refugee after his MOM said he should be locked up

https://www.dailymail.co.uk/news/article-15078101/judge-released-decarlos-brown-iryna-zarutska-stabbing.html

Statement on the Assassination of Charlie Kirk – by Daniel Miller, 10Sep2025

https://texianpartisan.com/news/statements/statement-on-the-assassination-of-charlie-kirk/

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Via a Mormon blog I follow – 11Sep2025

I hope I’m wrong.

But tonight feels like some sort of invisible line has been crossed that we didn’t even know was there. The last time I felt like this was 9/11 when it was clear, without knowing the how and the what, that the world was about to change forever.

Like the rules of the game had been permanently altered and there was simply no going to back to the innocent, peaceful past.

I didn’t feel like this when an attempt was made on President Trump’s life. If I had to rationalise why I didn’t, I guess it’s because several US Presidents have been shot at and even assassinated. Somehow it was within the realms of the possible, no matter how awful.

But to murder a young father simply for doing debates and mobilising young people to vote for a party that represents half of America? This is something else.

Charlie’s death is a tragedy for his wife, his children and his family. I don’t pray often. I am praying for them tonight.

But I fear his murder will be a tragedy for all of us in ways we will only understand as time unfolds.

I hope I’m wrong. (Konstantin Kisin)

The entire Right has to band together. Enough of this in-fighting bullsh@t. We are up against demonic forces from the pit of Hell. They’re killing us in our churches. They tried to kill our president. They killed Charlie, one of our greatest advocates. Put the personal squabbles aside. Now’s not the time. This is existential. A fight for our own existence and the existence of our country. (Matt Walsh)

Like all of you, I am utterly stunned and heartbroken and sick to my soul today. It is unimaginable to write these words. I met Charlie Kirk when he was 18 years old, a young man so eager and determined that I immediately turned to a friend and said, “That kid is going to be the head of the RNC one day.” Charlie became even bigger and more important than that. It was a privilege to watch this principled man stand up for his beliefs and create the single most important conservative political organization in America. But more importantly, Charlie was a good man, a man who believed in right and wrong, who stood by his Biblical values. All of us will miss him, and I can’t imagine the pain of his beautiful young family, and we must all pray for them. And we must pick up the baton where Charlie left it, fighting for the things he believed in so passionately. And we must fight for a better America – an America where good people can speak truth and debate passionately without fear of a bullet. I weep for Charlie’s family, and I weep for my country today. (Ben Shapiro)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Jasmine Crockett’s Stance on Police Troubling Considering her Stance on 2A

https://bearingarms.com/tomknighton/2025/09/11/for-once-jasmine-crockett-gets-it-right-on-police-n1229866

“Law enforcement isn’t to PREVENT crime! Law enforcement solves crime, okay? That is what they are supposed to do.”

(Translation: the police aren’t there to protect you, they are there to draw the chalk outline of the dead person. You can defend yourself to decide who is in the chalk outline. – jlr)