Lumber has become expensive. A couple of 4x4s, some 2x4s and a 2×10, and I’m looking at painful amounts of money. Ouch.

Which brings us to working to a goal:

This cabinet will be knocked down and flat packed. We want this for events. All in all, it looks nice and will perform the functions we need.

I started looking at the materials required to make this. The costs for the lumber starts to get a little excessive. Mostly because of some wide boards that are required. In addition, we will be making more than one and some other pieces as well.

Which takes me to wood. Wood is what you find in trees and burn in your wood stove. Lumber is what you build from.

I have a lot of wood outback. I don’t even bother with all the pine that has fallen over the years because it is horrible for heating. And splitting it is painful.

In the best of all worlds, I would have some way to drag the wood out of the lot, load it into a wood mill, and then mill it to size. Base cost, about $3000. And I’m not sure if I can get the wood out. So add another $2k for the ability to move logs.

The next best thing would be to mill in place. This I’m willing to try. It requires a jib for my chainsaw and a willingness to mill. I expect to be able to pull some reasonable 4/4 lumber out this way. Beach, red oak, pine, elm and some other wood.

Ok, that tool comes first. Add a learning curve.

Now that I have that, I need to turn that 4/4 into useful lumber for building. There is nothing in that shelf unit that is beyond my skills. I’ve built furniture in the past. I expect to be able to build this.

Except I don’t have a place to build it. Which leads me to: I need a workbench:

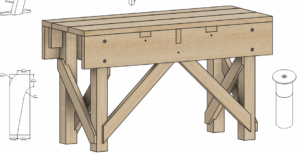

This is an English Joiners workbench. It has a torsion box interior to stabilize the top, The apron is 2×10 to add stability. There is diagonal bracing which is firmly attached to the rear apron and rear legs to stop racking side to side. And cross bracing for the trestles to stop forward and back motion.

It is held together with screws and construction adhesive. This is where I want to end.

For work holding, a wooden leg vise will be available as well as planing stops, hold down holes, Batten stop and a crochet.

All of this will make it easy for me to work on the cabinets that I intend to make.

Except… The front apron needs to be flat and parallel on both major sides. This is no problem. I have the planes to do this. I have the knowledge of how to do it and some of the skills required.

All I need is a workbench with a planing stop.

What I require is a flat surface to use as a pseudo surface plate for woodworking. The only thing that might come close is the floor of my shop. Which is full and where it is not full, it is oily.

The answer is to build a workbench.

The workbench that I would make is a “low Roman workbench”. It would have a laminated top of 2x4s on edge. I don’t need to make the faces of the 2x4s “flat” I just need to make them flat enough for glue up. I can do this without a reference surface.

To make the surface of the low Roman workbench flat, I can just plain it flat. This can be done with the good plains I already have and some winding sticks.

In addition, the low Roman workbench is better suited for sawing.

For now, I’m stuck between making both workbenches or using my plainer to plain the front apron. If I use the plainer, I get to a workbench faster.

Well, my rubber ducks, thank you for that option.

I’ll use machine tools to get my joiners workbench up and running soonest. I might build the low Roman a bit later.

Now to have time and good weather to build this thing. It looks to be a three day build.

Leave a Reply to Chris Johnson Cancel reply