Engineering

Three men were abducted by aliens. A mathematician, a physicist, and an engineer.

When they woke up, they were on one side of a room, and on the other side was a beautiful blonde with a pistol beside them.

A disembodied voice says, “You are allowed to move half the remaining distance across the room each time you move. If you can make it to the other side, you can do what you will with the blonde, and you will be set free. If you don’t make it to the other side, you can either kill yourself or be taken for the probings.”

The mathematician sits and thinks for a little, calculates a bit more, then says, “It is impossible; no matter how many steps you take, there will still be more to go.”

With that, the mathematician picks up the gun and shoots himself.

The engineer and physicist sit in shock for a moment before the physicist speaks up.

“You know that mathematicians are stuck in their numbers. They have no real-world experience. I’m going to test his hypothesis.”

So he does; on the first move he makes it halfway, on the second he is 3/4s of the way, and on the next move he’s 7/8s. He’s making progress, but he realizes he will never make it all the way.

He returns to his side of the room, picks up the gun, and offs himself.

The engineer is nearly in shock. He looks at the two bodies and then gathers himself up. He starts the process of crossing the room.

After over 50 moves, he reaches out, grabs the blonde, yanks her into his arms, and says, “Good enough for all practical purposes.”

For All Practical Purposes

During the age of steam, engineers developed a working idea of how steam engines worked and how to measure them. These men were not dumb; they understood nature, and they understood Newtonian physics. They developed formulas to guide them as they designed new engines.

What were they interested in? They wanted an efficient engine that produced enough work to make it worthwhile.

What is efficiency in a steam engine? How much steam it consumes. A boiler is only capable of producing a limited amount of steam. That is based on the amount of heat put into the system along with how efficient the boiler is at transferring the heat into water to force a phase change.

The more efficient the boiler, the less fuel it took to run. Coal and wood cost money.

An inefficient steam engine consumes more steam, which requires the boiler to produce more steam, which means more fuel.

The work that an engine produces is defined as brake torque and brake horsepower. Torque is how much rotational force is being produced, while horsepower is force of distance. Steam engines produce good torque over the entire range of supported speeds.

They had methods of measuring torque and horsepower. They could also measure the pressure of the steam. They knew the size of the piston they were using. They needed an expression for determining torque and horsepower before they designed an engine, much less built it.

The formula was P.L.A.N., which is pressure times length of stroke in feet times area of the piston face times the number of power strokes per minute.

They can easily measure stroke length, piston area, and power strokes per minute; those are simple things that can be measured with a ruler and a counter over time. But how do you measure the pressure?

The pressure changes over the time of the power stroke. At the start of the stroke, the cylinder has not yet filled with steam; it is still entering, so it is lower than the source. As the cylinder begins to fill, the piston starts moving, increasing the volume while reducing the pressure. The cutoff takes place, and now no more steam is being allowed to enter, and the steam that is there just expands, decreasing the pressure even more.

At every moment of that cycle there is a different pressure in the cylinder. With advanced math, you might be able to calculate it at every step then integrate over time.

These guys stuck some sort of pressure gauge on the cylinder and somehow measured the average (mean) pressure.

This is the value they used. The Mean Effective Pressure or MEP.

This is good enough for all practical purposes.

What is the starting pressure

If you have a closed system, the pressure at every point is the same. A steam engine is not a closed system. There is always steam being vented to the outside, either directly to the atmosphere or into a condenser.

This produces a sequence of pressure drops. The pressure is then built up as new steam flows from the boiler. All of this happens very rapidly, but it does take time. To reduce the amount of pulsing that hits the boiler, we use a steam reservoir, which is part of the steam chest.

When the flow of a fluid is stopped rapidly, it causes a “hammer” effect. Opening and closing the valves, allowing steam to flow into the cylinder and then stop can do just this.

The following video explains the water hammer phenomenon.

By putting that reservoir closer to the valves, we can stop that phenomenon from hammering on the boiler.

But how do we know what the pressure is in the steam chest? We might assume it is the same as the boiler, but it takes time for the steam chest to fill. The amount of time it takes to fill and stabilize is dependent on the size and shape of the piping from the boiler to the steam chest.

We need to measure or otherwise determine what the effective pressure in the steam chest is.

So we have a basic idea of what the pressure might be.

How much does it cost

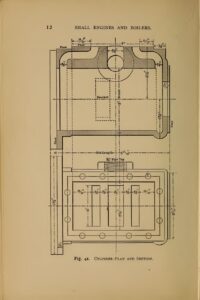

Steam travels from the steam chest into the cylinder via a steam passage. The shape, wall texture, and size of the steam passage affect the speed at which the steam enters the cylinder. In addition, we have the mass of the fluid (air/steam) that is in the passage when we start pressurizing it.

We need to measure how long it takes to reach the cylinder port and how long it takes to fill the cylinder. The smaller the passage, the more velocity you lose and the longer it takes to fill the cylinder. If it takes longer to fill the cylinder than the admission stage of the cycle then we are not getting full power from the engine.

Sometimes these passages are drilled and plugged or covered. Other times they are cast into the cylinder body. If cast, the quality of that core determines the texture/smoothness of the walls of the passage. Other times, they are drilled in a straight line to intersecting passages. Regardless of how they are made, they are a complex shape that causes turbulence and can cause other issues.

We need to know how much we lose, the cost, of getting steam from the steam chest into the cylinder.

And what happens in the cylinder

As stated before, the cylinder volume is constantly changing. The volume is decreasing when we start allowing steam into the cylinder. This lead steam acts like a cushion or spring to help start the piston back in the other direction. Remember that we are not only using energy to create power/work, we are also using energy to reverse the direction of the cylinder.

With a standard 4 stroke engine, we have four stages: Intake, where we suck a fuel air mixture into the cylinder. Compression, where the fuel air mixture is compressed for maximum efficiency. The power stroke, where the fuel has burned and the expanding gas is driving the piston. Finally, we have the exhaust stroke, where the expended gases are pushed out of the cylinder.

Only the power stroke puts energy into the system. The other three strokes are wasted. The energy to move the piston comes from other cylinders or energy stored in a flywheel.

With the steam engine, as the volume is decreasing, the expended steam is being pushed out the exhaust port. In simple engines the exhaust port is the same as the inlet port. Just before top dead center, steam is allowed back into the cylinder, pushing against the piston. This slows the piston as it reverses direction. The steam pushes the piston away from the cylinder head, causing the volume to increase.

Before we reach bottom dead center, the inlet is cut off. The steam continues to expand, continuing to push on the piston. Finally the piston reverses direction, and the used steam is exhausted to the atmosphere.

We need to integrate the pressure at the surface of the piston over the entire cycle.

Computational Fluid Dynamics (CFD)

I have studied Finite Element Methods (FEM). CFD is a different from FEM but has many similar aspects. The gist is that we create a mesh of a volume. We set the initial conditions of every surface or point. The initial condition is the pressure and a velocity vector.

We then define some formulas that describe how the fluid acts. From this we propagate the initial conditions through the mesh to a “stable” result. We can then use that result as a new set of initial conditions and iterate another time step.

With this we can see pressure waves, velocities, and just about everything we need to know about the flow of the fluid through the mesh.

The great thing is that there are good, free CFD packages out there. I’m using OpenFOAM because I am using FreeCAD as my modeling software.

With FreeCAD you can build a “body” or “part”. A part is a single item. It can be created by additive or subtractive means. It could be a rough or machined casting or something made from bar stock.

The bodies are combined into “assemblies”. An assembly is a collection of parts that are connected with joints. Joints can be fixed, sliding, rotating, and a few others.

I’ve been able to take the parts of the steam engine I’ve modeled and create assemblies, which have shown me that I misread the prints. Meaning I’ve had to go back and redo the body/part which sometimes required redoing the assembly. An iterative process.

With a body, I should be able to create a negative of that body, representing the domain of for the CFD, which is what gets meshed.

I can use the CfdOF workbench to create meshes, set initial conditions, set the properties for the fluid, refine the mesh, and a dozen other things before passing the actual analysis off to OpenFOAM.

OpenFOAM runs for a long time and then produces results that I should be able to visualize. That has not been working all that well.

From this, I should be able to calculate what MEP is at every location and step of the system.

And I’m stuck here. Not totally stuck, but more of the I know I don’t know something, I’ll have to figure it out.

But what about the rest

All of the above is just to get a cylinder that will produce the power I need or want.

From there we move into the mechanical world. Here we have to design the components to meet the requirements of the cylinder.

How big should the piston rod be? It has no rotational or angular forces applied to it, just tension and compression. This is an FEM calculation or uses simple analytical calculations.

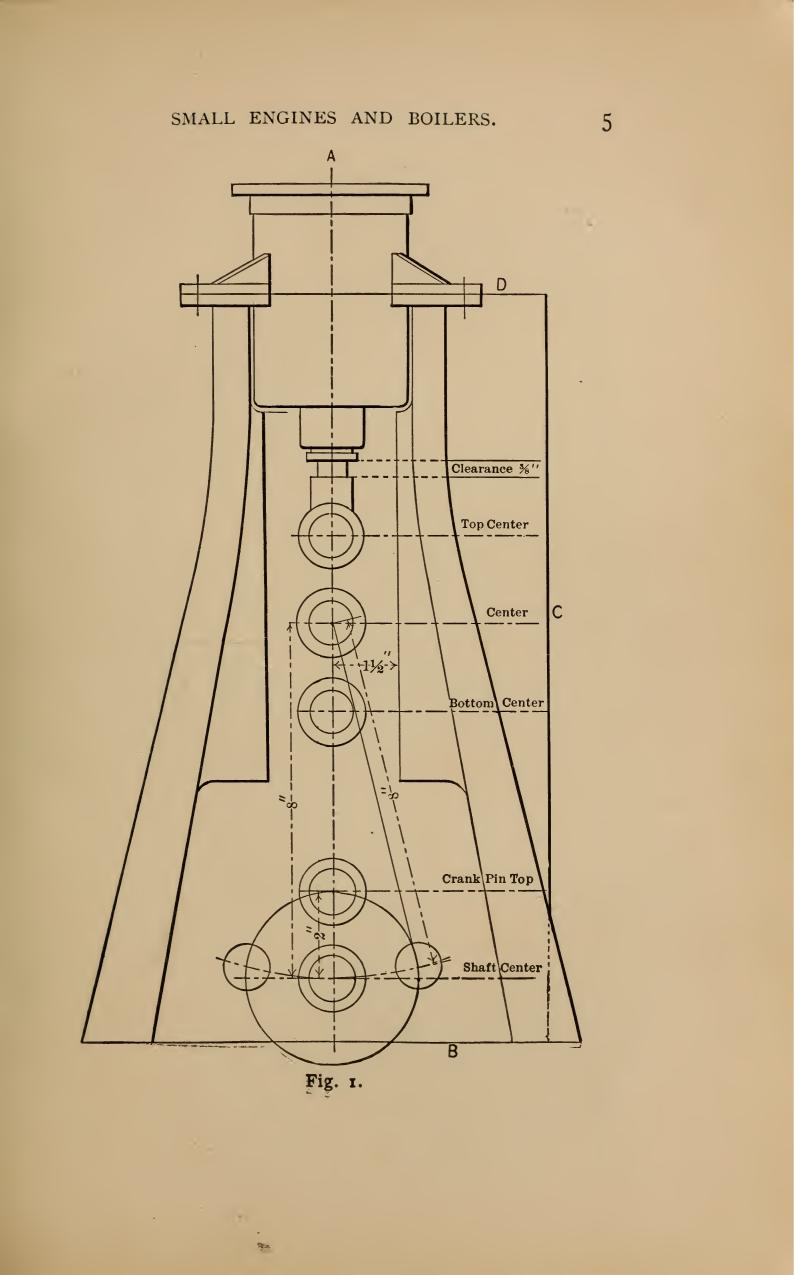

The connecting rod gets more complex. The big end is connected to the crankpin, which moves in a circle. The small end is attached to the end of the piston rod. It moves in a linear motion. We need to evaluate the forces in play on the crosshead pin and the crankpin to make sure they are strong enough but not overkill. We need to design for reduced mass because mass changing directions takes energy.

We also have to worry about the vibrations we get from throwing the crankpin in a circle.

If you want to design a vibrating thing, just put a weight off-center on a spinning thing, and you get vibrations. We balance the wheels of our cars to remove that type of vibration. We have to balance the crank to remove as much of the vibration as possible.

But we have to know what the forces in play are at every stage of the cycle to know how to cancel them. Painful.

We need to know the size of the driveshaft. My small models use a 1/4 inch shaft. For my 1/2 HP engine, I doubt a 1/4 will be strong enough.

The shaft must ride in bearings that can withstand the reciprocating forces as well as the axial forces.

But why?

The answer is never simple, but for me I want to be able to enter a desired HP rating and torque rating and have a custom designed steam engine modeled.

I currently have an integrated spreadsheet with my 3D model. You can select or set the desired brake power you want at a given boiler pressure and a given RPM. This feeds into several formulas, which then drive the model.

Change the stroke in the spreadsheet, and everything from the cylinder through the final assembly changes to match that cylinder. It even goes so far as to define the number of screws or bolts in the cylinder flange, the size of those screws and bolts, as well as the proper torque values for those screws and bolts.

The next step is to get the steam passages correctly designed and sized. This will drive the steam chest which will drive other components.

In the end I should be able to have the system give me patterns for casting.